The Invisible Boiler & A Bureaucratic Black Hole

Living in a big city, one often finds interactions with city government to be an opportunity to fall into a black hole of process and procedure that all-too-often exists in these bureaucracies. We’ve all heard stories of ridiculous outcomes that result when interacting with a city or government official so inflexible they just follow the rules, regardless of how illogical the outcome is. This is one such story told from the perspective of a lowly property owner trying to navigate the bureaucracies of the New York City building department and the intricacies of its code.

The building that I live in has large cast iron radiators in all of the apartments, a steam boiler that heats up a large iron mass filled with water in the basement, and pipes to send hot steam throughout the building. This same type of system has likely been in use for nearly a hundred years in this building. When we first bought this property I had noticed that the boiler was noted with a handwritten ‘1995’. So, as one does when one needs to maintain a steam boiler pushing 30 years old with winter approaching, I diligently went down to the basement one evening to drain and flush the boiler.

Steam boilers work by heating a large iron mass filled with water and generating steam that is sent up iron pipes into cast iron radiators. The steam then condenses in the radiators and trickles back down the same pipe that it came up in, this is called a one-pipe steam system. As you can probably imagine, heating up water and running it through a cast iron system produces a lot of rust. Well, you probably don't know much about steam boilers, but you probably know that you shouldn't put your cast iron pots and pans in the dishwasher. So think about it, a boiler made out of cast iron is producing and sending steam to cast iron parts, running hot water and air through it the whole time. The result is ‘boiler juice,’ a liquid that looks more like coffee with heavy cream than water.

As I was getting ready to flush this nasty liquid out of the boiler I noticed a small leak underneath the burner. This was a very bad sign. Unlike many metals, cast iron is not one that is easy for welding and repairs. I knew enough to know what I was looking at: a terminal patient. The boiler was running and heating the building, but would not make it through this winter without a catastrophic leak.

As an experienced property investor with a whole bunch of relationships built up over many years, this was not a big deal. I picked up the phone and called "my guy." I have been working with this plumber for a number of years and we have done a number of large renovation jobs together. I called him and let him know that the boiler would have to be replaced, knowing full well that he only does large jobs with no interest in unclogging sinks and fixing faucets. As expected, he returned my text within a couple hours, and we scheduled a time for him to come take a look.

A few days had passed when I heard a buzz at my door. Looking out the window from my living room I noticed that it was the plumber coming to take a look and chat about the boiler. I motioned for him to go down the stairs and underneath the stoop, so that I could meet him by the boiler. He nodded. I went downstairs and opened the door that provides access under the stoop of this 19th century tenement building. Upon greeting the plumber, I was struck by an overwhelming smell of stale cigarettes and machine oil. He is a great plumber and charges a great price, but most other plumbers that I interact with work hard to break old stereotypes about their profession, by maintaining a professional presence. We spent about 10 minutes looking at the boiler and talking about what needs to be done. After shaking hands, I was comforted by the knowledge that soon enough the leak will be gone, my tenants will be warm, and I will have a more energy efficient boiler to boot.

The next day, I got a text back from the plumber letting me know that he had reached out to a number of vendors to get some prices for a new boiler. As always I waited patiently. A few days had passed when I reached out to the plumber again inquiring about the new boiler. In the interim the boiler had continued to leak and I was spending time turning the boiler on and off to make sure the building stays sufficiently warm but preventing a flood in the basement. A day had passed since I had last texted the plumber and there was no reply. This was odd, so I waited until the next day and crafted another short text "hey, did you get the prices?" No response. Another two days, no response. I was getting prickly.

I decided to call a few other plumbers as backup knowing full well the severity of the leak could change dramatically without much notice. After reaching out to three different plumbers I gave my guy one last chance. When push comes to shove this is a business. It has to run like a business. When vendors and partners don't operate their business in the same manner it becomes quickly apparent that severing ties is the best way forward. As I anticipated, no response. If this plumber was looking for a sure-fire way to burn a bridge, he found it.

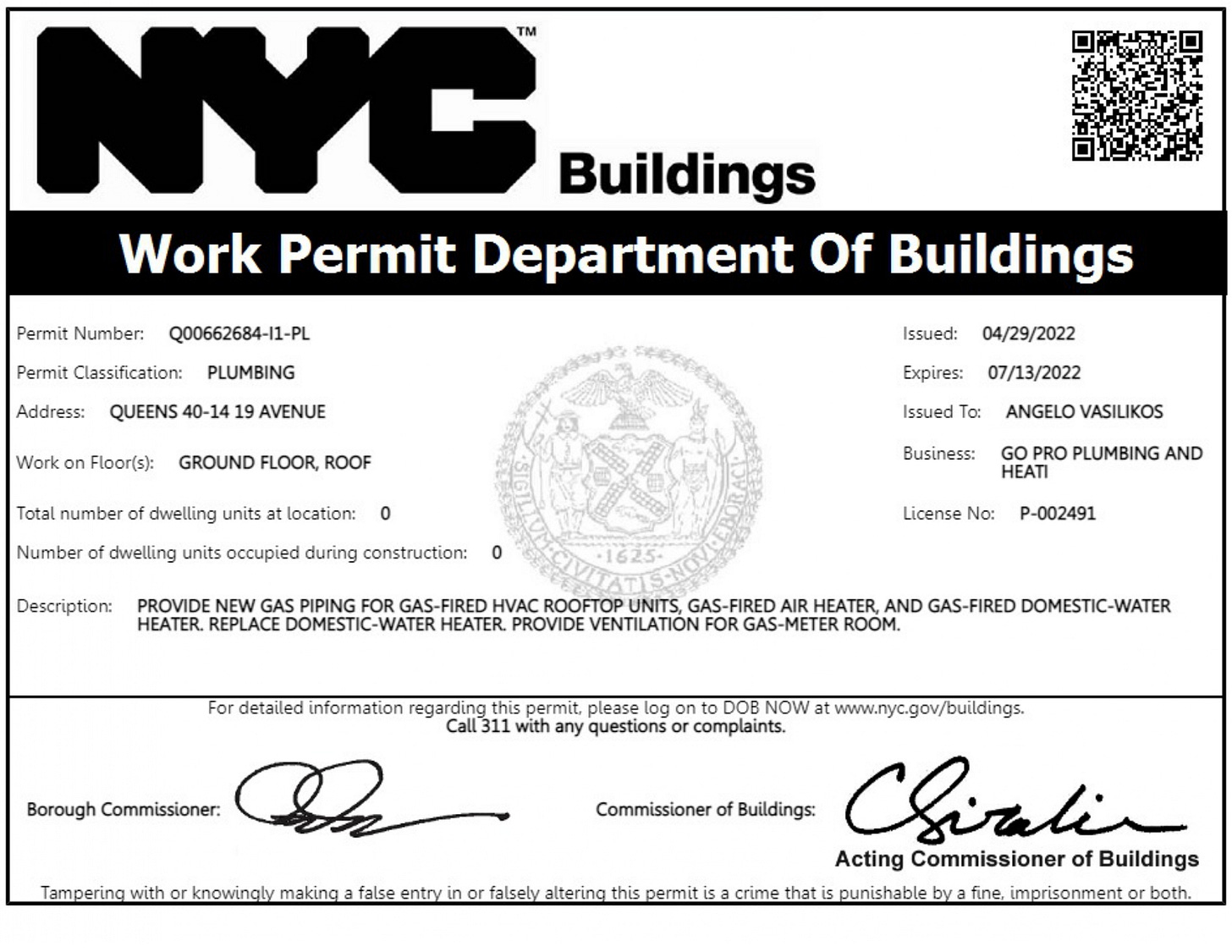

In the end, the choice was made to move ahead with one of the other vendors who came highly recommended from a fellow plumber friend. As you can imagine when doing anything in the city of New York, filing permits is a critical part of the process. As an additional layer of regulation, the city of New York requires the registration of each and every steam boiler, given that poor maintenance could turn them into a bomb. In this case, the permits were a breeze, it took 48 hours and we were in possession of a black and white piece of paper with magical properties of warding off building inspectors.

Installing a new steam boiler isn’t a small task, but two experienced plumbers and a couple of helpers had the job done in a few days. Steam boilers are an especially dangerous mechanical system, requiring safety to always be the top priority in its regulations. As such, steam boiler systems must be inspected annually and reported back to the building department by a licensed professional. Having owned this particular boiler for more than 20 years, I was quite familiar with a process that I had repeated more than 20 times. This time was different though, when a new boiler is installed a building inspector comes from the city to visually inspect the boiler.

Personally, I never worry about these inspections. I always work with license professionals and make sure that everything we do is by the law and up to code. To my surprise, when we did our first inspection the inspector came and refused to complete the inspection because of "missing paperwork." According to him we had requested the wrong type of inspection, as this was a new boiler install and not a replacement. I was dumbstruck. This boiler had been in this building for at least 30 years and I had been diligently filing my annual inspection reports since 2003.

Having failed the inspection, all we could do was gather our thoughts and figure out how to resolve the problem. The plumber said he would talk to his expeditor. On a side note, NYC building department bureaucracy is so bad that hiring a professional "expeditor" to simply navigate the maze and file the paperwork is standard practice. Our case needed further investigation by the expeditor.

By this time, we had installed the boiler and it was functional. So, waiting for the resolution of the bureaucratic Gordian knot was simply a matter of patience. After a couple of weeks, I got a call back reporting that the building department did not have any record of a boiler in the basement of the building. According to the expeditor the building departments digitization process had resulted in the loss of numerous paper-based documents that never made it into the digital database. It seems like all of our historical paperwork was somewhere in that black hole. The expeditor joked “I guess you have an invisible boiler.”

To resolve the problem, we had to file the application as if the boiler was a brand-new installation. This would mean that we would need to trigger an inspection of both the boiler and the gas line. The new application and filing fees would be an additional $2,000 and replacing the gas line given the new code would also be another $1,500, on top of the $22,000 project cost. This was a painful and unnecessary cost created by a bureaucracy that can't keep its records straight.

We scheduled our follow up inspection and waited the requisite few weeks for the day to arrive. This time the inspectors reviewed the boiler and found no deficiencies. As we walked out of the basement, the inspector walked across the street to get a better view of the chimney. He squinted his eyes and started asking questions about the roof. This was not a good sign. Specifically, he was asking about the height of the top of the chimney relative to the roof deck. I pointed out to the inspector that everything in the building was built up to code, not so long ago. It didn’t work. The inspector insisted we extend the chimney. Another $3000 expense I was subject to because I had to file a new boiler permit, after the city lost our paperwork.

This is a case where having records and being organized made no difference. The difference here was having the money set aside to absorb a significant and unexpected cost. Somebody else screwed up and I paid the price. Sometimes, that is just the cost of doing business. Running your own business is all about getting through the challenges and succeeding in spite of the reality that sometimes shit happens. Keep your head down and grind through!

If you've found value in these insights and want to continue your journey of real estate wisdom, we invite you to subscribe to The Property Alchemist. Don't let your real estate dreams remain just dreams. Empower yourself with the knowledge and insights that can turn your investment visions into concrete reality. Subscribe to The Property Alchemist today and take the first step towards becoming a master of real estate alchemy. Your next successful project is just a subscription away!